Liyang Shares: high-efficiency and high-power LED light source products and applications

2016-08-06

With the rise of the third generation of semiconductors represented by GaN and SiC, high-efficiency high-power LED as a semiconductor light source, compared with traditional lighting sources, more energy saving, longer service life, lower voltage, and shorter opening time. High-power LED technology has developed rapidly and has a very broad application prospect, and the reliability of the device is the guarantee of its wide application.

The structure of the LED itself, can be divided into four broad categories of high-power LED light source, one is a SMD surface chip package light source, one is a single imitation lumen LED light source, another is an integrated high-density package LED light source, and the last is a COB substrate package light source.

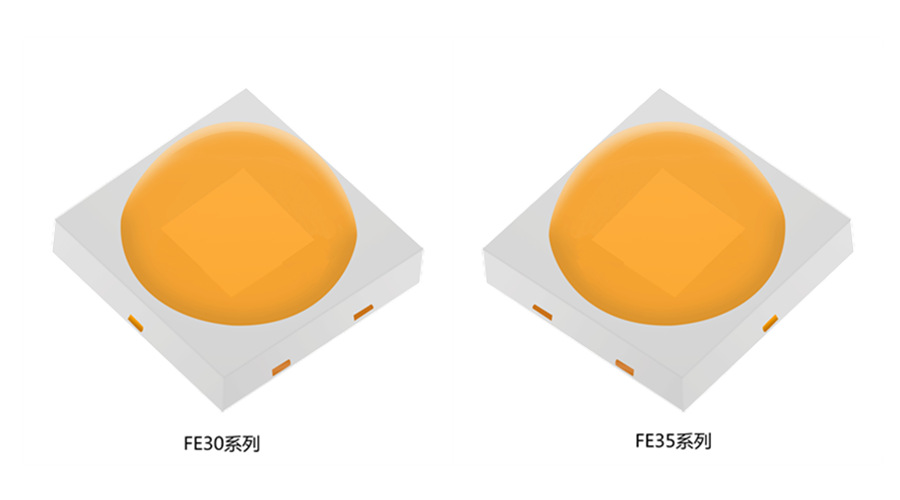

SMD patch light source

SMD light source refers to the surface mount light-emitting diode, which has the advantages of large luminous Angle, high production efficiency, good precision, low virtual welding rate, light weight, small volume, etc., which helps to improve production efficiency, and different facility applications. At present, the latest products of Liyang stock inversion new FE30/FE35 series, the use of imported EMC bracket, support 1A large current input and output, the maximum power up to 3W, luminous flux up to 400lm, while completely eliminating the leakage caused by gold wire, flicker, dead lamp and other reliability problems. At the same time FE30/FE35 patent Molding design, relative to the previous generation of flat packaging products, improve the light output rate of 10%-15%, due to the increase of the front shooting area, make the product hot channel smoother, easier to secondary light distribution. The market positioning of FE30/FE35 is very clear: replace the traditional 1W imitation lumen products, upgrade the flat EMC3030 products, ceramic substrate 3030/3535 products, replace similar XPG series products, and enter the market through super stability and ultra-high cost performance.

Because the product has the characteristics of small size, large luminous Angle, strong anti-UV ability, etc., it can be flexibly combined to form a modular type, light guide plate type, light gathering type, reflection type and other forms of lighting source. Widely used in interior lighting, advertising decoration, urban lighting and other fields.

COB substrate type LED light source

COB package refers to the chip directly on the substrate for binding packaging, mainly to solve the problem of low-power chip manufacturing high-power LED products, through the substrate direct heat dissipation, not only can reduce the manufacturing process and cost of the support, but also has the advantage of reducing thermal resistance of heat dissipation, with ultra-thin, anti-collision compression, light Angle close to 180°, strong heat dissipation ability, etc. Has a better optical diffuse color muddy light effect. Take the latest flip-side integrated COB series products D4046 as an example: no gold wire package, using the new welding process independently developed by Liyang shares, support large current input, input current can reach 1.5 times of the same formal products, but also with high-density packaging, small area high lumen output and other characteristics. The appearance of D4046A solves the thermal conductivity problem of the integrated light source, and the inverted structure makes its hot channel smoother and greatly improves the service life of the product!

Because of its unique product characteristics, COB light source is widely used in indoor and outdoor lighting, downlights, mining lights, spotlights, track lights and other fields.

Integrated high-density packaged LED light source

Integrated high-density packaging products usually use a single or double layer aluminum substrate as heat sink, the single chip or multiple chips are directly fixed on the aluminum substrate (or copper substrate) with solid adhesive, and the p and n electrodes of the LED chip are bonded on the thin copper plate on the surface of the aluminum substrate. The number of chips arranged on the base is determined according to the size of the power required, and the integrated LED is packaged in an optically designed shape using a material with a high refractive index.

Such products are mainly used in outdoor lighting, street lamps, searchlights, floodlights and other fields.