Lepower Shares: Talk about LED packaging and market application

2016-10-06

As the connection point of the upstream and downstream industries, LED packaging plays a key role in connecting the previous and the next. Under the development of LED high light efficiency, power, high reliability and low cost, the requirements for packaging have increased. As a result, the packaging industry has been in the rapid drive and development stage of new materials and new processes in recent years, and emerging packaging forms and technologies have emerged endlessly, such as EMC, COB, flip, CSP and so on. Next, Liyang shares will take you into the world of LED packaging!

What is LED packaging

LED packaging refers to the LED chip and bracket by epoxy resin or silicone and other materials wrapped up the process, its main role is to complete the output signal, protect the normal work of the tube core, output visible light, etc., the packaged light source device can make the chip isolated from the outside world, to prevent impurities in the air corrosion chip circuit caused by photoelectric performance decline.

Role of encapsulation

To realize the function of input electrical signal, protect the normal work of the chip and output visible light, including the design and technical requirements of both electrical and optical parameters.

1, the led chip can be packaged into electronic components for commercial use.

2, protect the chip, prevent radiation, water vapor, oxygen and external damage.

3, improve the reliability of components.

4, improve and enhance chip performance.

5, provide chip cooling mechanism.

6, design a variety of packaging forms to provide different product applications.

Encapsulation mode

Since the photons emitted by the pn junction region of the LED chip are non-directional, that is, they have the same probability of being emitted in all directions, so not all the light generated by the chip can be emitted. How much light can be emitted depends on the quality of the semiconductor material, the chip structure, the geometry, the material inside the package and the packaging material. Therefore, for LED packaging, it is necessary to choose the appropriate packaging method according to the size and power of the LED chip.

At present, Liyang Shares mainly adopt the following technologies in packaging devices:

1, flip no gold wire packaging technology

Flip no gold wire packaging, based on flip welding technology, on the basis of traditional LED chip packaging, reduce the gold wire packaging process, save the wire rack, wire, leaving only the chip with phosphor and packaging adhesive use, combined with superconducting aluminum substrate, through multiple experiments with different lines and surface treatment process matching, effectively improve the product light efficiency and pressure. Completely solve the problems caused by the gold wire welding, poor contact, such as not bright, flicker, light decay and so on.

2, flip product application welding technology

The original flip products in the actual production of welding need to be welded through auxiliary equipment, Liyang Shares with different structures, materials, process matching, successful introduction of copper sheet welding technology, through reflow welding to complete the point to point welding, greatly improving the speed and quality of product welding.

3, precipitation process packaging technology

Liyang Group independently developed white light precipitation process packaging technology, in order to reduce the radiation heat of LED packaging as a starting point, through secondary vacuuming, preliminary separation of phosphor and silicone, and then through special equipment with temperature, time, glue characteristics, so that the phosphor completely precipitates to the surface of the substrate, and completely covers the chip, when the light generated by the phosphor radiation heat, It will quickly conduct out through the substrate, thereby improving the heat resistance of the LED light source.

4, low display refers to high light efficiency packaging technology

Through the special chip band with narrow half-wave width phosphor, improve the color purity, eliminate the influence of stray light, make the light more pure, reduce the display finger, light efficiency has been greatly improved, so as to independently develop low display finger high light efficiency packaging technology, the main application range of 2800-3000K, used to replace the traditional street lamp field.

5, high display refers to high light efficiency packaging technology

Liyang Shares independently developed high display finger high luminous efficiency LED light source, using the full spectrum of mixed materials, display finger coverage of about 30-98. 10% higher than conventional light sources.

Market and application

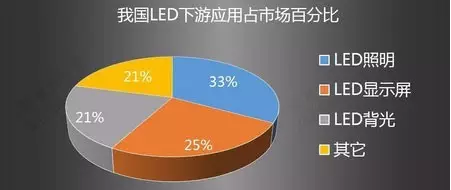

The downstream applications of LED packaging are mainly LED lighting, LED display and LED backlight.

LED market rise in LED backlight, mature in LED lighting, with the maturity of medium power technology, car LED market in recent years has attracted much attention, the major LED packaging factories have begun to layout.

In terms of application field, "COB is suitable for commercial lighting lamps, focusing on light color and light quality; Inversion is suitable for use in mobile phone flash and street lights; CSP in the field of LED backlight, mobile phone flash market has been growing; EMC occupies a large market share in the market of alternative lamps with the largest market capacity, such as bulbs, tubes, panel lights, downlights, etc. EMC lamp beads have been used in large numbers.